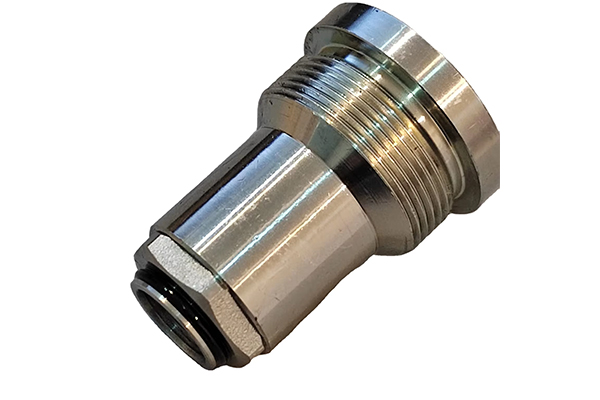

How does the hydraulic quick connector ensure that the oil will not be lost when the pipeline is disconnected and reduce the oil pressure loss?

Release Time : 2024-12-19

the one-way valve core collides, forcing the valve core to leave the tapered hole of the joint body, so that the oil in the two pipes can communicate, thereby restoring the normal operation of the hydraulic system.

In addition, the hydraulic quick connector also adopts a two-stage sealing design to further enhance its sealing performance. This design not only provides a reliable seal when the connector is connected to prevent oil leakage, but also maintains a sealed state when disconnected to ensure that the oil will not be lost. At the same time, the material and surface treatment process of the connector body are carefully selected and optimized to improve its wear resistance and corrosion resistance, thereby extending the service life of the connector and reducing oil pressure loss.

In addition to the above design, the installation and use of the hydraulic quick connector are also crucial. During installation, it should be ensured that the model, size and thread of the connector match the piping characteristics, and the correct installation steps and torque requirements are followed. During use, improper operations such as hitting, bending or stretching the connector should be avoided to avoid damaging the sealing structure and check valve inside the connector.

In summary, the hydraulic quick connector ensures that the oil will not be lost when the pipeline is disconnected through the internal check valve, two-stage sealing design, and correct installation and use methods, thereby reducing oil pressure loss. This feature makes the hydraulic quick connector have a wide range of application prospects and important value in hydraulic systems.

In addition, the hydraulic quick connector also adopts a two-stage sealing design to further enhance its sealing performance. This design not only provides a reliable seal when the connector is connected to prevent oil leakage, but also maintains a sealed state when disconnected to ensure that the oil will not be lost. At the same time, the material and surface treatment process of the connector body are carefully selected and optimized to improve its wear resistance and corrosion resistance, thereby extending the service life of the connector and reducing oil pressure loss.

In addition to the above design, the installation and use of the hydraulic quick connector are also crucial. During installation, it should be ensured that the model, size and thread of the connector match the piping characteristics, and the correct installation steps and torque requirements are followed. During use, improper operations such as hitting, bending or stretching the connector should be avoided to avoid damaging the sealing structure and check valve inside the connector.

In summary, the hydraulic quick connector ensures that the oil will not be lost when the pipeline is disconnected through the internal check valve, two-stage sealing design, and correct installation and use methods, thereby reducing oil pressure loss. This feature makes the hydraulic quick connector have a wide range of application prospects and important value in hydraulic systems.