How to ensure the sealing performance of Hydraulic Quick Connectors?

Release Time : 2024-11-07

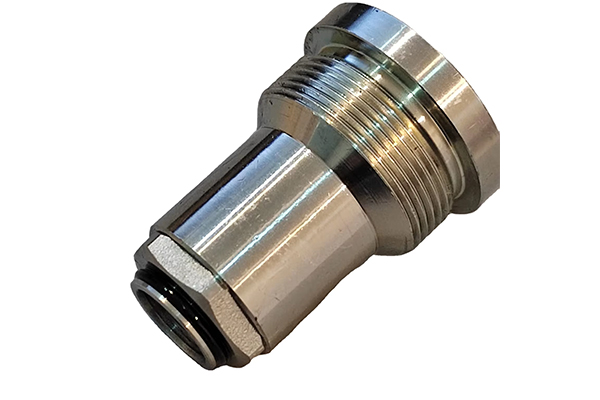

As an important connecting component in the hydraulic system, the sealing performance of Hydraulic Quick Connectors is directly related to the stability and reliability of the entire system. Ensuring the sealing performance of Hydraulic Quick Connectors can not only prevent fluid leakage, but also effectively prevent external impurities from entering the system, thereby ensuring the normal operation of the hydraulic system. The following are some key measures to ensure the sealing performance of Hydraulic Quick Connectors.

First, material selection is crucial. Hydraulic Quick Connectors usually use corrosion-resistant, high-temperature-resistant, and wear-resistant materials, such as stainless steel, plastic or synthetic rubber. These materials can effectively resist the erosion of fluids and improve the durability and sealing performance of the joints. When selecting materials, it is also necessary to consider the temperature, pressure, corrosiveness and other conditions of the joint use environment to ensure that the selected materials can meet the actual working requirements.

Secondly, the sealing design must be reasonable. The sealing structure of Hydraulic Quick Connectors generally uses O-rings, gaskets or other seals. The design of these seals should be able to effectively prevent fluid leakage. During the production process, it is necessary to ensure that the size and shape of the seals meet the standards to avoid sealing failure due to processing errors. At the same time, the material and hardness of the sealing ring should also be selected according to the working environment and fluid characteristics of the joint to ensure the sealing effect.

Furthermore, the correct installation method and standardized operating procedures are equally important to ensure the sealing performance of Hydraulic Quick Connectors. During installation, the connection between the joint and the pipe should be clean and free of impurities to avoid affecting the sealing effect. At the same time, tighten according to the specified torque or pressure to ensure that the joint connection is firm and reliable. During use, the sealing state of the joint should be checked regularly, and the seal should be replaced in time if wear or aging is found.

In addition, the pressure and temperature of the fluid have a direct impact on the sealing performance of Hydraulic Quick Connectors. When designing and selecting joints, the working pressure and temperature range of the fluid should be fully considered, and the appropriate joint model and sealing material should be selected. At the same time, during use, overload and long-term high-speed operation should be avoided to avoid excessive pressure and wear on the joint, affecting its sealing performance.

Finally, regular maintenance and care are also the key to ensuring the sealing performance of Hydraulic Quick Connectors. The joints should be cleaned, lubricated and inspected regularly to extend their service life. At the same time, it is also necessary to regularly replace the filter and check the oil quality to prevent impurities from entering the system and affecting the sealing effect.

In summary, ensuring the sealing performance of Hydraulic Quick Connectors requires multiple aspects such as material selection, sealing design, installation operation, fluid conditions, and maintenance. Only by comprehensively considering these factors and taking effective measures can we ensure that Hydraulic Quick Connectors can maintain a good sealing effect under various working conditions, thereby ensuring the stable operation of the hydraulic system.

First, material selection is crucial. Hydraulic Quick Connectors usually use corrosion-resistant, high-temperature-resistant, and wear-resistant materials, such as stainless steel, plastic or synthetic rubber. These materials can effectively resist the erosion of fluids and improve the durability and sealing performance of the joints. When selecting materials, it is also necessary to consider the temperature, pressure, corrosiveness and other conditions of the joint use environment to ensure that the selected materials can meet the actual working requirements.

Secondly, the sealing design must be reasonable. The sealing structure of Hydraulic Quick Connectors generally uses O-rings, gaskets or other seals. The design of these seals should be able to effectively prevent fluid leakage. During the production process, it is necessary to ensure that the size and shape of the seals meet the standards to avoid sealing failure due to processing errors. At the same time, the material and hardness of the sealing ring should also be selected according to the working environment and fluid characteristics of the joint to ensure the sealing effect.

Furthermore, the correct installation method and standardized operating procedures are equally important to ensure the sealing performance of Hydraulic Quick Connectors. During installation, the connection between the joint and the pipe should be clean and free of impurities to avoid affecting the sealing effect. At the same time, tighten according to the specified torque or pressure to ensure that the joint connection is firm and reliable. During use, the sealing state of the joint should be checked regularly, and the seal should be replaced in time if wear or aging is found.

In addition, the pressure and temperature of the fluid have a direct impact on the sealing performance of Hydraulic Quick Connectors. When designing and selecting joints, the working pressure and temperature range of the fluid should be fully considered, and the appropriate joint model and sealing material should be selected. At the same time, during use, overload and long-term high-speed operation should be avoided to avoid excessive pressure and wear on the joint, affecting its sealing performance.

Finally, regular maintenance and care are also the key to ensuring the sealing performance of Hydraulic Quick Connectors. The joints should be cleaned, lubricated and inspected regularly to extend their service life. At the same time, it is also necessary to regularly replace the filter and check the oil quality to prevent impurities from entering the system and affecting the sealing effect.

In summary, ensuring the sealing performance of Hydraulic Quick Connectors requires multiple aspects such as material selection, sealing design, installation operation, fluid conditions, and maintenance. Only by comprehensively considering these factors and taking effective measures can we ensure that Hydraulic Quick Connectors can maintain a good sealing effect under various working conditions, thereby ensuring the stable operation of the hydraulic system.